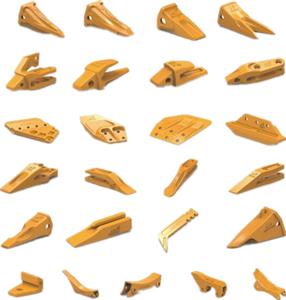

excavator bucket teeth

-

Hot

Caterpillar Cat Excavator Bucket Teeth Replacement

Cat excavator teeth replacement cycle: The replacement cycle of the cat excavator teeth should be determined according to the construction environment and the degree of wear of the bucket teeth. For example, the excavator has been doing earthwork work, so the wear degree of the cat excavator teeth is relatively small, and it is generally replaced every 4-5 months. . If it is a rock-type cat excavator teeth, the frequency of replacing the bucket teeth is faster. Like granite, it takes about a week to replace the bucket teeth. Of course, this cycle is not fixed, and it depends on the quality of the bucket teeth and the meticulousness of the actual operation. and so on to determine the replacement frequency of bucket teeth.

cat bucket teeth for sale cat excavator bucket teeth replacement caterpillar excavator teeth cat excavator teethEmail Details -

Hot

Cheaper Best Quality Komatsu pc200 Bucket Teeth

Buying Guide of komatsu pc200 bucket teeth: If your excavator is doing earthwork, the frequency and demand for replacing komatsu pc200 bucket teeth every year is relatively small, then it is recommended that you choose forging and casting komatsu pc200 bucket teeth, although the price is much higher, but the service life, production process and quality are all is optimal. If the requirement for the number of bucket teeth is relatively large, then the cost performance of the komatsu pc200 bucket teeth is required to be relatively high, then the precision cast bucket teeth perform well in terms of price, quality, cost performance and wear resistance.

Email Details -

Hot

Komatsu Excavator Bucket Teeth

1. During the use of the komatsu bucket teeth of the excavator, the outermost teeth of the bucket wear 30% faster than the innermost teeth. After a period of use, the inner and outer komatsu bucket teeth of the bucket should be replaced. 2. The excavator driver should pay attention to the angle of digging during the operation, try to master it when digging, and the komatsu bucket teeth are perpendicular to the working face when digging down, so as to avoid breaking the bucket teeth due to excessive inclination. 3. Be careful not to swing the digging arm left and right under the condition of large resistance, so that the komatsu bucket teeth and tooth adapter are easily broken due to excessive force on the left and right sides, and the design of the force on the left and right is not considered.

Email Details -

Hot

Kobelco Excavator Bucket Teeth

Selection of kobelco bucket teeth: When purchasing bucket teeth for excavators, the first thing to look at is the working environment in which the bucket teeth are used to determine what type of kobelco bucket teeth. First, generally dig soil, loose sand, etc. with flat kobelco bucket teeth. Secondly, RC-type bucket teeth are used for digging massive hard rock, and TL-type kobelco bucket teeth are generally used for digging massive coal seams. In addition, in the actual operation process, most people like general-purpose RC bucket teeth. Kyushan recommends that you do not use RC type bucket teeth, it is best to use flat kobelco bucket teeth, because RC bucket teeth wear out after a period of time, increase the digging resistance and waste power, while the flat bucket teeth always maintain a sharp surface during the wear process, reducing the digging resistance, Save fuel.

kobelco bucket teeth kobelco excavator bucket teeth rock teeth for excavator bucket excavator teeth priceEmail Details -

Hot

Doosan Excavator Bucket Teeth

Doosan excavator bucket teeth: 1. To protect the whole bucket, the bucket teeth are wear parts. Since the bucket wears a lot when shoveling soil and stones, the doosan excavator bucket teeth are added to protect the bucket. Just imagine what a bucket without bucket teeth would wear... 2. Make the operation more delicate. We drive the excavator to draw a dragon painting style on the ground. Imagine that the delicate operation cannot be achieved without the reference of doosan excavator bucket teeth. 3. Easy to dig and shovel. The doosan excavator bucket teeth are conical with a gap in the middle. The force of the entire bucket is smaller and the pressure becomes larger, making it easier to shovel and dig things up... 4. After digging hard things, it has a buffering effect on the whole machine, etc.

excavator bucket shanks excavator bucket teeth manufacturers mini digger ripper tooth rock bucket teethEmail Details -

Hot

Hyundai Excavator Bucket Teeth

Speciality of hyundai bucket teeth: 1. Adjustable cutting angle by rotating up to 1800 in its holder; 2. Easy hyundai bucket teeth replacement with purpose- built extraction tool; 3. Compact construction facilitating complicated cutting geometry; 4. High durability due to wear-resistant manganese steel; 5. Tungsten carbide inserts on cutting edge and on both flanks; 6. Optimum transition from teeth to teeth holder to cutting blade; 7. Each hyundai bucket teeth is positioned in optimum cutting geometry; 8. High strength resulting from forging; 9. Optimal protection of teeth holder.

hyundai bucket teeth hyundai excavator bucket teeth tooth bucket excavator excavator bucket teeth suppliersEmail Details -

Hot

Volvo Excavator Bucket Teeth Replacement

1.We are manufacturer of volvo excavator bucket teeth and have our own factory. 2.Over 10 years experience in Construction machinery industry. 3.High quality material, wear-resistant and long life working time of volvo bucket teeth. 4.Delicate product with competitive price. 5.Various type volvo excavator bucket teeth and weight for your option. 6.Awarded ISO9001 certificate. 7.12 months after sales service warranty. Buying bucket teeth is definitely not as simple as paying first hand and delivering with one hand. If you choose it, you will have a qualitative guarantee for the completion of excavators, buckets and engineering work. Easy to break can understand!

volvo bucket teeth volvo excavator bucket teeth volvo excavator teeth volvo excavator teeth replacementEmail Details -

Hot

Hitachi Excavator Bucket Teeth

1.We are factory for hitachi bucket teeth. 2.Good impact toughness and wear resisitance . 3.Smooth and nice-looking finish . 4.CNC drilling machine provide you both beautiful and accurate round and punch holes which can match with the bolt very well . 5.Automatic electrostatic spray painting line . 6.Competitive and reasonable price of hitachi excavator bucket teeth . 7.Short delivery time:30 days per 20ft container .

hitachi bucket teeth hitachi excavator bucket teeth frost tooth for mini excavator frost teeth for excavatorEmail Details