excavator bucket

-

Hot

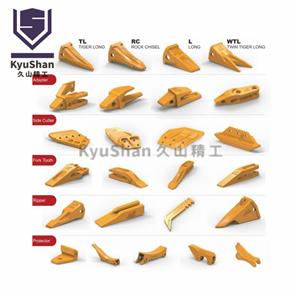

Professional Excavator Bucket Teeth Supplier

We are professional excavator bucket teeth suppliers Excavator bucket teeth are important consumable parts on excavators, similar to human teeth. They are combined bucket teeth composed of tooth bases and tooth tips, which are connected by pins. Since the worn out part of the bucket teeth is the tip of the tooth, just replace the tip. Classification according to the environment in which the bucket teeth of the excavator are used. Excavator bucket teeth can be divided into rock teeth (for iron ore, quarry, etc.), earthwork teeth (for excavating soil, sand, etc.), conical teeth (for coal mines). According to the bucket tooth seat: the excavator bucket tooth can be divided into vertical pin bucket tooth (mainly Hitachi excavator), horizontal pin bucket tooth (Komatsu excavator, Carter excavator, Daewoo excavator, Kobelco excavator, etc.) , Rotary bucket teeth (V series bucket teeth).

bucket teeth suppliers excavator bucket teeth suppliers case backhoe bucket teeth excavator bucket teeth for saleEmail Details -

Hot

All Kinds Of Fuel Oil Caterpillar Filters For Excavator

The function of the oil filter is to caterpillar filters out the sundries, gums and moisture in the oil, and deliver clean oil to each lubricating part. In order to reduce the frictional resistance between the relatively moving parts in the engine and reduce the wear of the parts, the oil is continuously transported to the friction surface of each moving part to form a lubricating oil film for lubrication. The engine oil itself contains a certain amount of gum, impurities, moisture and additives. At the same time, during the working process of the engine, the introduction of metal wear debris, the entry of debris in the air, and the generation of oil oxides make the debris in the oil gradually increase. If the oil directly enters the lubricating oil circuit without being filtered, the sundries contained in the oil will be brought into the friction surface of the moving pair, which will accelerate the wear of parts and reduce the service life of the engine.

excavator bucket teeth suppliers drive excavator rock teeth for excavator bucket mini excavator undercarriageEmail Details -

Hot

All Part Numbers Cat Caterpillar Oil Filters For Excavator

Caterpillar excavator filter maintenance 1. The caterpillar oil filters is the core component of the filter. It is made of special materials and is a wearing part, which requires special maintenance and maintenance; 2. When the caterpillar oil filters has been working for a long time, the filter element has intercepted certain impurities, which will lead to an increase in pressure and a decrease in flow. At this time, it needs to be cleaned in time;

Email Details -

Hot

Supplier Donaldson Kobelco Fuel Filter

Replacement time of kobelco fuel filter: Hydraulic excavators generally need to be replaced after 2000 hours of operation, otherwise the system will be polluted and cause system failure. According to statistics, about 90% of hydraulic system failures are caused by system pollution. In addition to checking the color, viscosity, and smell of the oil, it is also necessary to check the oil pressure and air humidity. If you work in a higher altitude and lower temperature environment, you must also pay close attention to the carbon content, colloid (olefin) and sulfide in the engine oil, as well as the impurities, paraffin and moisture content in the diesel. In special circumstances, if the machinery uses low-grade diesel oil (sulfur content in diesel oil is 0.5﹪~1.0﹪), the kobelco fuel filter and machine filter should be replaced every 150h; Machine filter. Use crushers, vibratory rammers and other equipment that have a heavy load on the hydraulic system. The replacement time of the hydraulic oil return filter, pilot filter and respirator filter is every 100h. Cost-effective fuel filtration does not equate to cutting corners We pay attention to every little detail (to save you from worries) We use quality components to manufacture quality filters - both high-end and standard models

mini excavator track rollers excavator chain link excavator hydraulic parts excavator bucket bushingsEmail Details -

Hot

All Part Numbers Donaldson Excavator Air Filter

The working environment of excavators is generally harsh and dusty. The excavator air filter is mainly used to protect the corresponding parts of the excavator, reduce the entry of impurities and dust, improve the work efficiency of the excavator and prolong the service life. There are many types of excavator filter elements, the common types are excavator air filter, air conditioning filter element, hydraulic oil pipeline filter element, fuel filter element, hydraulic oil return filter element, pilot filter element, hydraulic oil suction filter element, etc. These filter elements play an important role in the maintenance of excavators. play an important role.

track adjuster excavator link belt excavator parts excavator bucket teeth pins excavator track idlerEmail Details -

Hot

Donaldson Brand All Kinds Of Excavator Oil Filter

Is the higher the filtration precision of the excavator oil filter, the better? For an engine or equipment, an appropriate filter element should achieve a balance between filtration efficiency and ash holding capacity. Using a excavator oil filter with a high filtration precision may shorten the service life of the filter element due to the low ash capacity of the filter element, thereby increasing the risk of premature clogging of the oil filter element.

excavator bucket wear parts parts of excavator machine excavator bucket spacers excavator hydraulic pump priceEmail Details -

Hot

80mm Bucket Pins

There are several reasons why the 80mm bucket pins are relatively easy to break. The tooth roots are worn out, the 80mm bucket pins are not firm and easy to break, and the tooth roots are repaired by electric welding, and the strength of the bucket teeth is not enough during use. The tooth library is deformed and the tooth library is large

Email Details -

Hot

50mm Excavator Pins For Bucket

50mm excavator pins, which is widely used in the connection of moving parts such as excavators, cranes, grab buckets, etc., for example, when the bucket is working, as the connection between the bucket teeth and the bucket tooth seat working at the front end, dust or sand, etc. Foreign objects will run into the gap between the bucket tooth pin and the pin hole. When the bucket tooth pin needs to be replaced, the foreign object makes the bucket tooth pin difficult to disassemble, causing trouble to people.

digger buckets for sale near me rake bucket for mini excavator v ditch bucket for mini excavator 36 inch bucket for mini excavatorEmail Details -

Hot

30mm Bucket Pins For Excavator

Advantages / Features of 30mm bucket pins: Our company has already passed ISO9001-2000 international quality control system. and adopts advanced examintion,manufacturing equipments and technology of precision casting to make the products with the impact and hardness.

18 inch bucket for mini excavator largest excavator bucket mini ex buckets ripper bucket for excavatorEmail Details